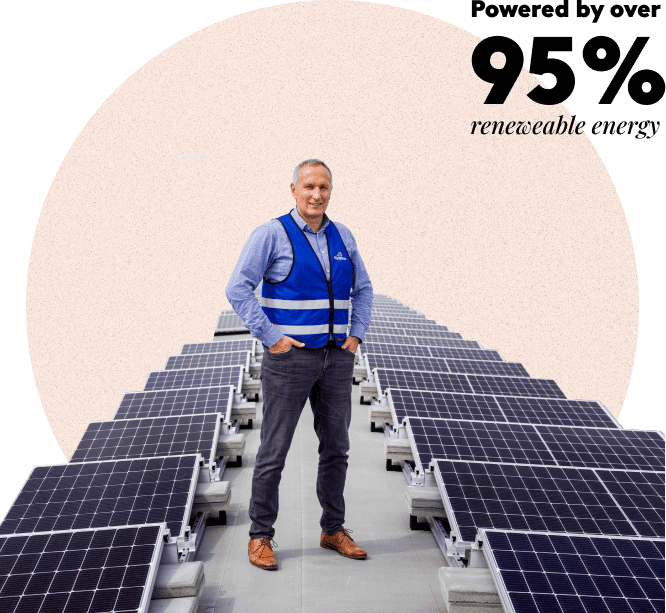

Henk Bassie, Managing Director Kingspan Insulation Continental Europe, at Jönköping

Jönköping was designed and constructed with energy efficiency at its core, starting with the building envelope. Over 150k m2 of Kingspan insulated panels and over 15k m2 of Kingspan insulation boards enclose the facility. Natural daylight enters the building through 130 nano prismatic rooflights supplied by Kingspan Light & Air, improving occupant wellbeing and reducing the need for artificial light.

The efficiency of the factory process has been optimised by using Kooltherm® insulated piping and Kingspan insulated panels for the dryers and laminators.

Jönköping is a blueprint for what we, and others, can achieve when energy and carbon efficiency are considered as core elements of planning and design.

“The new Kooltherm® line in Jönköping, Sweden, uses more than 95% renewable energy and is exemplary because our Planet Passionate principles were considered in the design stage, from inception to commissioning.”

Deon Joubert

Kingspan Insulation installed a rooftop solar PV installation at its manufacturing facility.

It’s more than efficiency in buildings. Upfront or embodied carbon in materials is a growing priority.

Future